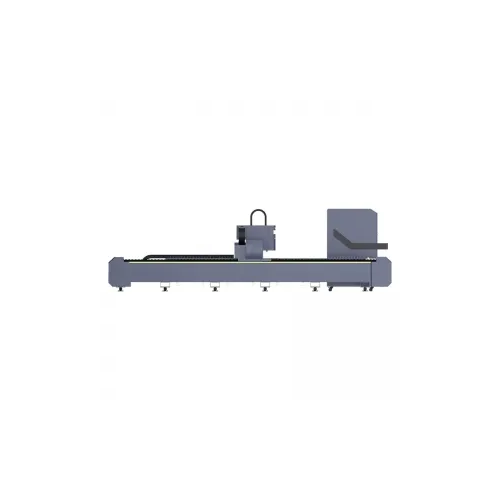

Full Cover Metal Plate Fiber Laser Cutting Machine

The fiber laser cutting machine is a mature product of WID Laser which has reached the domestic advanced level. This series of products are the first choice for the metal material processing industry.

Product Description

Product Description

A full cover fiber laser cutting machine is a type of laser cutting equipment that utilizes a fiber laser source to cut metal plate materials. It is designed with a full cover system that protects the operator from the laser beam, ensuring their safety during the cutting process. The machine operates by focusing the laser beam onto the material, generating high heat to melt and vaporize the material, allowing for precise cutting and engraving. This type of laser-cutting machine is widely used in industries such as metal fabrication, automotive, aerospace, and electronics.

The machine body is a honeycomb carbon structure. After annealing treatment, the beam is made of aerospace aluminum casting. The bed has thick steel plates and the entire bed is welded. It has extremely high strength and stability and the machine runs at a very fast speed.

Advantage

Anti-radiation observation window

The observation window in the full-enclosed design uses imported anti-radiation glass, which is convenient for viewing, blocks laser radiation, and protects eyesight.

Dual separate monitoring and Programming

The two interfaces operate independently, which is convenient for energy saving. The monitoring picture is clear and smooth, and the programming operation is stable and efficient.

High frequency stable beam

The laser source frequency is up to 10Khz, and more stable light output to ensure cutting stability.

High cleaning treatment

The bed’s sectional smoke exhaust design has a large adsorption force, and fast smoke exhaust speed purifies the air, protects the environment, and escorts the operator’s health.

Technical parameters

|

Model |

WID-3015E |

WID-4020E |

WID-6020E |

WID-6025E |

|

Power |

3000-4000W |

3000-4000W |

3000-4000W |

3000-4000W |

|

Height Adjustment Tracking Sensor System |

accuracy ±0.1mm |

accuracy ±0.1mm |

accuracy ±0.1mm |

accuracy ±0.1mm |

|

Working Area (L*W) |

3000*1500mm |

4000*2000mm

|

6000*2500mm

|

6000*2500mm

|

|

X/Y-axis Positioning Accuracy |

±0.03mm/m

|

±0.03mm/m

|

±0.03mm/m

|

±0.03mm/m

|

|

X/Y-axis Repositioning Accuracy |

±0.05mm

|

±0.05mm

|

±0.05mm

|

±0.05mm

|

|

No-load Speed |

100m/min |

100m/min |

100m/min |

100m/min |

|

Acceleration |

1.5G |

1.5G |

1.5G |

1.5G |

|

Loading Weight of Platforms |

1500kg |

2500kg |

2800kg |

3000kg |

Machine details

High Beam Quality, Faster, More Effective

Plate welded bed

The machine bed undergoes stress relief annealing and natural aging treatment to eliminate internal stress, so that the bed maintains good mechanical properties, with good tensile properties, toughness, and hardness, the average weight of the bed is 30-50% higher than that of other China suppliers.

IPG laser source

Up to 6KW output from a single module

High-level vertical integration

Excellent material processing performance

High power with great beam quality

Compact design, stable performance and maintenance-free.

Cutting Sample