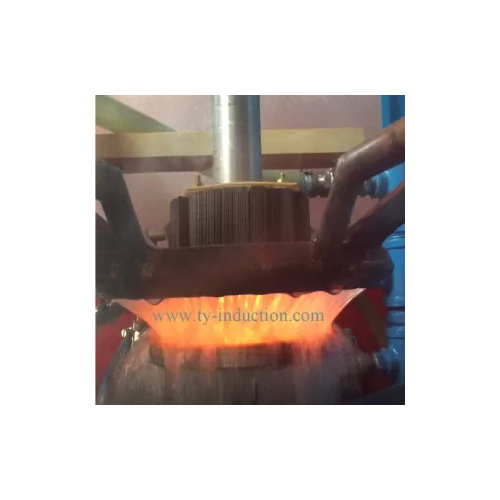

Billet/Bar Induction Total Heating Equipment

TY Induction can offer a complete Billet Total Heating Induction Equipment with full-automatic or Semi-automatic material handling machine, water cooling system and temperature control.

Product Description

TY Induction induction heating machines are widely used in mechanical forging heating processing, industrial heat treatment manufacturing, tool induction brazing manufacturing, food heating processing and other fields. Based on the principle of induction technology updating and customer demand, TY Induction has been striving to produce industrial induction heating equipment with its own characteristics and independent core technology in the induction heating industry. With the renewal of induction heating equipment from generation to generation, and our rich experience in induction heating industrial applications, we provide high quality industrial induction heating equipment to end customers worldwide

The difference between medium and high frequency induction heating equipment

Different frequencies

Induction heating equipment with a frequency of 1-10Khz is usually considered as medium frequency induction heating equipment, and induction heating equipment with a frequency of 50Khz or more is considered as high frequency induction heating equipment.

Different quenching depths

The quenching depth of the two is different depending on the frequency of the induction heating equipment. The quenching depth of medium frequency induction heating equipment is generally 3.5-6mm, while the quenching depth of high frequency induction heating equipment is 1.2-1.5mm.

Different heat transmission diameter

Medium-frequency induction heating machine has great advantages in the heat transmission of workpieces. It is mainly used for the heat transmission heat treatment of workpieces. The workpiece with a diameter of 45-90mm can be subjected to a transheat heat treatment. However, high frequency induction heating equipment can only dilute thin and small workpieces.

Induction heating VS other heating methods

Induction heating differs from some common heating methods in that it does not rely on convection and radiation to transfer heat to the surface of the product. Instead, heat is generated on the surface of the product by an electric current, and then transferred from the surface to the product by heat conduction. The depth of direct heating using induction current depends on the electrical reference depth.

Unlike some combustion methods, induction heating can be precisely controlled independent of batch size. By varying the current, voltage and frequency of the induction coil, fine-tuned engineering heating can be achieved, making it ideal for precision applications such as surface hardening, tempering and annealing. High precision heating is critical for critical applications such as automotive, aerospace, fiber optics, ammunition bonding, wire hardening and spring wire tempering. Induction heating is well suited for specialty metal applications involving titanium, precious metals and advanced composites. The precise heating control provided by induction is unmatched. In addition, utilizing the same heating principles as vacuum crucible heating applications, induction heating can be applied continuously in the atmosphere. An example is bright annealing of stainless steel tubes.