Square Flat Top Locked Woven Wire Screen

Square Flat Top Locked Woven Wire Screen

Product Description

Wires in flat top locked screens get locked only on one side of the panel. Square weave wire mesh comes with several benefits which include a fixed aperture opening size, perfectly locked wires, flat top of the screen for easier material flow and reduced wear.

Material: Stainless steel wire, high carbon steel, carbon steel, nickel steel and nonferrous wire

Advantages of Square Weave Wire Mesh:

1. Locked Wires for Optimal Security: The flat top locked screens are engineered to ensure that wires are securely locked on one side of the panel. This unique design guarantees structural integrity, enhancing the overall durability of the mesh.

2. Consistent Aperture Opening: Experience a fixed aperture opening size, eliminating any irregularities and ensuring uniform screening results. This consistency contributes to accurate separations and efficient sorting processes.

3. Smooth Material Flow: The flat top surface of the square wire mesh facilitates seamless material flow. This design element reduces bottlenecks, prevents material accumulation, and promotes uninterrupted production cycles.

4. Reduced Wear and Longevity: The precisely locked wires and sturdy construction minimize wear and tear, extending the lifespan of the square steel mesh. This results in a cost-effective solution that requires less frequent replacements.

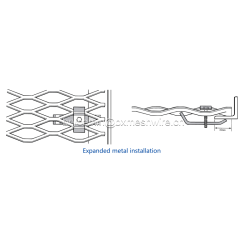

Square Wire Mesh Weaving Method

• Pre-crimped wire mesh is made of wire diameters ranging from 1.5mm to 16mm mm. Square mesh panels can be used for windows, partitions, roasting of meat and flour sieving or mine screens.

• In the pre-crimping process, the wire is first formed (crimped) in precision machines using rotary dies that precisely define the spacing of the wires. This insures that the wires are locked firmly together at the intersections. The pre-crimped wires are then assembled in custom designed screen assembly machines (looms).

• When the open area is important, extra crimps between the intersections provide a more rigid weave and provide locking and tightness for light wires in relation to the large openings.

• Due to the crimping process, the square woven wire mesh from Changte have very accurate and consistent openings and are woven after crimping. It is typically preferred for vibrating screens and many other applications where sizing is critical.

Applications of Square Weave Wire Mesh:

1. Industrial Screening: Excel in industries like mining, petroleum, and chemical, where precise screening is imperative for efficient operations. Achieve accurate separations of materials, ensuring quality output.

2. Construction Sector: In the construction industry, square wire mesh panels are instrumental in creating sturdy structures. It's used for reinforcing concrete, providing stability, and ensuring structural integrity.

3. Food Industry: Ensure food safety with stainless steel square mesh, used for food machinery and processing. It prevents contamination and maintains hygiene standards during production.

4. Craftsmanship: Discover its potential in creating intricate handicrafts and wire baskets. The mesh's flexibility and durability make it an ideal choice for artistic projects.

5. Filtration and Grading: The square welded wire mesh's reliable aperture size and structural integrity make it suitable for filtration purposes, whether it's grading solid materials or filtering liquids.