Flattened Expanded Metal

Flattened Expanded Metal

Product Description

Flattened Expanded Metal Sheet Introduction

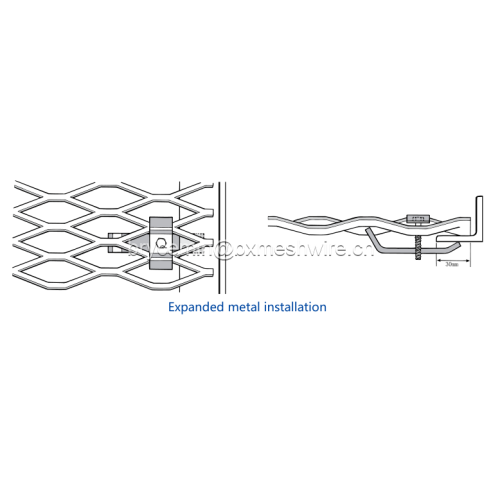

Flat expanded metal is standard expanded metal that has been cold flattened, leaving a smooth flat surface with diamond-shaped openings. During this process, the length of the sheet is usually stretched by about five percent. After the expanded metal is flattened, the expanded metal is sent through a straightening machine to maintain its flatness. As a flat expanded metal mesh supplier, Boxing provides flat expanded metal mesh made of various materials such as carbon steel, aluminum, stainless steel, etc.

Features of Flattened Expanded Metal

-

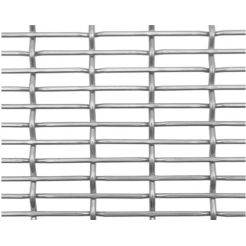

Strength and Durability: Flattened expanded metal is known for its strength and durability. The metal sheet undergoes a process of stretching and flattening, which enhances its structural integrity and load-bearing capabilities. This makes it suitable for applications that require a sturdy and long-lasting material.

-

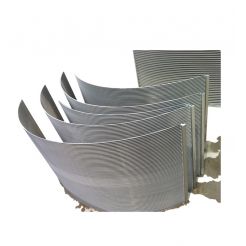

Surface Smoothness: As the name suggests, the flattened expanded metal has a smoother surface compared to standard expanded metal. This smoothness is achieved through the flattening process, which makes it more suitable for applications where a flat surface is desired, such as architectural uses, walkways, and decking.

-

Open Area: Despite being flattened, expanded metal maintains a high open area, which allows for good airflow, visibility, and light transmission. This property is often exploited in applications like ventilation systems, security screens, and fencing.

-

Versatility: Flattened expanded metal is available in a wide range of materials, including steel, aluminum, stainless steel, and more. This versatility in material options makes it suitable for various environments, whether they require corrosion resistance, aesthetic appeal, or specific mechanical properties.

-

Customizable Patterns and Sizes: We can create flattened expanded metal with different patterns and opening sizes to suit specific design requirements. This customization allows for adapting the material to different functional and aesthetic needs.

-

Cost-Effective: Due to its manufacturing process, flattened expanded metal tends to be more cost-effective than other solid sheet alternatives. It provides the benefits of a solid metal sheet while using less material, which can translate to cost savings.

-

Ease of Fabrication: Flattened expanded metal is relatively easy to fabricate, cut, and shape using standard metalworking tools. This makes it suitable for a wide range of DIY and professional projects.

-

Security and Safety: The interlocked diamond-shaped openings of flattened expanded metal provide security and safety benefits. It's often used for security screens, barriers, fencing, and partitions where visibility and ventilation are important.

-

Acoustic Properties: Depending on the application and specific pattern used, flattened expanded metal can have acoustic benefits. It can be used in soundproofing panels, baffles, or other structures designed to control sound reflections and transmission.

-

Aesthetic Appeal: Flattened expanded metal can be used for architectural purposes due to its unique texture and patterns. It's often used in facades, decorative panels, and other design elements to add visual interest and texture.

Applications:

Flattened expanded metal is a versatile material that finds applications in various industries due to its unique properties and characteristics. It is created by slitting and stretching a metal sheet to create a pattern of openings.