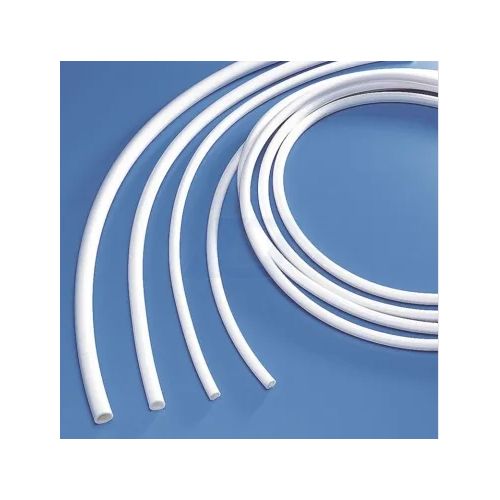

PTFE Extruded Tube

Are you in need of high-quality PTFE extruded tubes for your industrial applications? Look no further than PTFE Tube!

Product Description

PTFE Extruded Tube: A Versatile Solution for Industrial Applications

Are you in need of high-quality PTFE extruded tubes for your industrial applications? Look no further than PTFE Tube! So, let's dive right in and discover the world of PTFE extruded tubes! PTFE extruded tubes, offered by PTFE Polymer, are a versatile solution that finds application in a wide range of industries. Welcome to contact us for detailed information!

Characteristic of the products:

PTFE tube is made by plunger extrusion of suspension polymerized PTFE resin. Among all the existing plastics, PTFE has the best corrosion-resistance and dielectricity.

Specifications of Extruded tube

1. Flat and tidy surface, no defects, crevices and separations.

2. Low minimum order quantity.

3. no defects.

4. no crevices and separations.

5. corrosion-resistant for different corrosive conditions, heat exchanger.

Applications

1) Insulating Cover for Conductors and Pipe for Corrosive Fluids

PTFE extruded tubes find extensive usage as insulating covers for conductors and pipes carrying corrosive fluids. The excellent electrical insulation properties of PTFE make it a preferred choice for covering conductors, protecting them from external environmental factors and minimizing the risk of electrical failures.

Moreover, these tubes act as a barrier, preventing corrosive fluids from damaging the underlying materials, ensuring the longevity and reliability of the systems they are employed in.

2) Lead Insulating Sleeve

In certain applications, the need for insulation extends beyond electrical conductors. PTFE extruded tubes can be utilized as lead insulating sleeves, providing reliable insulation for lead wires and cables.

The high dielectric strength of PTFE ensures optimal insulation, minimizing the risk of electrical leakage or short circuits. Additionally, PTFE's chemical resistance properties make it an ideal choice for protecting lead wires in harsh environments where corrosive substances are present.

3) Corrosion-Resistant Pipe

Corrosion poses a significant challenge in various industries, especially when dealing with aggressive chemicals or fluids. PTFE extruded tubes offer an effective solution as corrosion-resistant pipes.

The inherent non-reactive nature of PTFE allows it to withstand the harshest corrosive environments, making it an excellent choice for transporting aggressive fluids without the risk of degradation or leakage. By using PTFE extruded tubes as pipes, industries can ensure the integrity of their fluid handling systems and prevent costly maintenance or replacements.

4) Corrosion-Resistant Insulating Pipe for Different Corrosive Conditions

PTFE extruded tubes also serve as corrosion-resistant insulating pipes in diverse corrosive conditions. The ability of PTFE to resist chemical attack from a wide range of substances makes it suitable for applications where corrosive fluids need to be insulated and transported.

Whether it's corrosive acids, bases, or solvents, PTFE extruded tubes offer unparalleled resistance, enabling safe and reliable operation in challenging environments.

5) Heat Exchanger

The exceptional thermal stability of PTFE extruded tubes makes them an excellent choice for heat exchangers. These tubes can withstand high temperatures, ensuring efficient heat transfer without compromising the structural integrity of the system.

By utilizing PTFE extruded tubes in heat exchangers, industries can enhance energy efficiency and prolong the lifespan of their equipment.

PTFE Tubing Properties

1. Exceptional Chemical Resistance

One of the key advantages of PTFE extruded tubes is their exceptional chemical resistance. These tubes can withstand exposure to corrosive chemicals, acids, and bases without degrading or losing their physical properties. This makes them ideal for applications in industries such as chemical processing, pharmaceuticals, and food processing.

2. High Temperature Stability

PTFE extruded tubes offer excellent thermal stability, making them capable of withstanding high temperatures without losing their integrity. They can handle temperatures ranging from -200°C to +260°C (-328°F to +500°F), ensuring reliable performance in extreme environments. This attribute makes them suitable for applications in aerospace, automotive, and electrical industries.

3. Low Friction Coefficient

The low friction coefficient of PTFE extruded tubes contributes to their remarkable non-stick properties. These tubes exhibit a very low surface tension, enabling easy flow of fluids and preventing clogs or build-up. This feature makes them an ideal choice for applications such as fluid transfer, lubrication systems, and pneumatic equipment.

4. Electrical Insulation Properties

Another noteworthy characteristic of PTFE extruded tubes is their excellent electrical insulation properties. These tubes have a high dielectric strength, making them perfect for insulation in electrical and electronic applications. They provide reliable protection against electrical arcing, making them suitable for wiring harnesses, cable assemblies, and more.

5. Excellent Weatherability

PTFE extruded tubes offer exceptional weather resistance, allowing them to withstand harsh outdoor conditions. They are resistant to UV radiation, moisture, and extreme temperatures, making them suitable for outdoor applications such as cable protection, outdoor lighting, and signage.

Discover the Unmatched Excellence of PTFE Extruded Tubes by Zhejiang Delong Teflon and Plastic Technology Co., Ltd.

Are you in search of top-quality flexible packaging solutions? Look no further! Zhejiang Delong Teflon and Plastic Technology Co., Ltd. is a leading manufacturer specializing in a wide range of high-quality flexible packaging options. With our exceptional expertise and dedication to excellence, we proudly present our stellar product, the PTFE Extruded Tube.

Unleashing the Potential of PTFE Extruded Tubes

At Zhejiang Delong, we understand the importance of delivering exceptional products that exceed industry standards. Our PTFE Extruded Tubes showcase the pinnacle of excellence in the realm of flexible packaging. Boasting an annual output value of 1500 tons, our company is committed to meeting your demands with fast delivery and competitive prices, ensuring your satisfaction.

Unrivaled Corrosion Resistance and Anti-Aging Endurance

One of the outstanding advantages of our PTFE Extruded Tubes is their unmatched corrosion resistance, making them a prime choice for various industries. Whether it's handling aggressive chemicals, corrosive fluids, or challenging environments, our tubes provide a reliable barrier, safeguarding your materials and ensuring the longevity of your systems. You can trust in the impeccable quality of our PTFE Extruded Tubes to protect your valuable assets.

Exploring the Superior Properties of PTFE Tubing

PTFE tubing, including our exceptional PTFE Extruded Tubes, exhibits a range of properties that set it apart from other materials. Its non-reactive nature ensures compatibility with a vast array of substances, providing a reliable and safe conduit for your operations. The exceptional thermal stability of PTFE tubing allows it to withstand high temperatures without compromising its structural integrity, making it an ideal choice for various applications.

Flexible Solutions Tailored to Your Needs

We understand that every project has unique requirements. That's why our PTFE Extruded Tubes are available in a variety of sizes to accommodate your specific needs. Whether you require small-diameter tubes for intricate applications or larger sizes for heavy-duty operations, we have you covered. Our dedication to customization ensures that you will find the perfect fit for your project, eliminating any compromises in performance or functionality.

Choose Excellence, Choose Zhejiang Delong

In a competitive market, it's crucial to stay ahead of the curve. By choosing our PTFE Extruded Tubes, you gain a significant advantage over your competitors. Our commitment to producing superior products, combined with our informative and customer-centric approach, sets us apart. With our tubes, you can rest assured that you are utilizing the highest quality materials available, enhancing your operations and satisfying your clients' expectations.

Conclusion

When it comes to flexible packaging, Zhejiang Delong Teflon and Plastic Technology Co., Ltd. stands out as a trusted and innovative manufacturer. Our PTFE Extruded Tubes exemplify our dedication to excellence, offering unmatched corrosion resistance and anti-aging endurance. With a wide range of sizes available, we tailor our solutions to meet your specific needs.

Choose Zhejiang Delong for superior PTFE Extruded Tubes that outshine the competition and elevate your operations to new heights of success. if you are interested in our ptfe extruded tube, please contact us as soon as possible.

Frequently Asked Questions (FAQs)

Here are some frequently asked questions about PTFE extruded tubes:

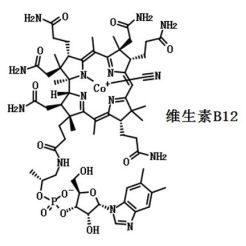

1. What is PTFE?

PTFE stands for Polytetrafluoroethylene, a synthetic fluoropolymer of tetrafluoroethylene. It is a high-performance polymer known for its exceptional properties such as chemical resistance, high temperature stability, low friction, and electrical insulation.

2. How are PTFE extruded tubes manufactured?

PTFE extruded tubes are manufactured through a process called extrusion. The PTFE resin is melted and forced through a die, resulting in the formation of a continuous tube. The tube is then cooled and cut into the desired lengths.

3. What sizes are available for PTFE extruded tubes?

PTFE extruded tubes are available in a wide range of sizes to accommodate various application requirements. They can be produced in standard sizes or customized to meet specific dimensions.

4. Can PTFE extruded tubes be used for high-pressure applications?

Yes, PTFE extruded tubes can handle high-pressure applications. They have excellent burst strength and can withstand high pressure without deformation or failure.