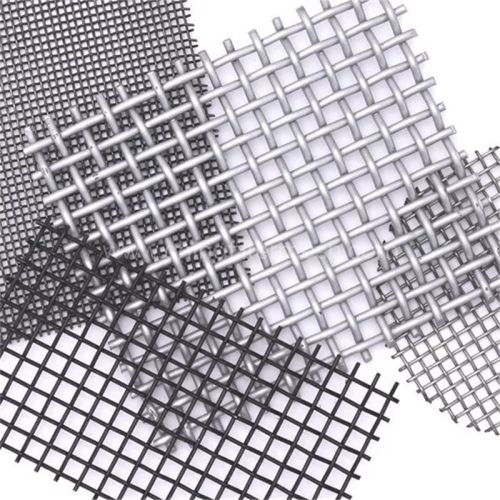

Crimped Wire Mesh

Crimped Wire Mesh

Product Description

Crimped Wire Mesh is an important member of woven wire mesh family, which is also known as mining sieves or screen. It is made of pre crimped wire to form a tight structure.

Due to its unique manufacturing process and excellent performance, crimped wire mesh has become an indispensable material in industrial production and daily life. Its widespread applications in screening, filtration, protection, and decoration highlight its immense potential and value across various fields.

Crimped Wire Mesh for Filtration

Benefits of Crimped Wire Mesh for Filtration

Strength and Durability: The crimping process adds structural integrity, making it resistant to wear and tear.

Versatile Applications: Suitable for liquid and air filtration in industries such as mining, food processing, water treatment, and pharmaceuticals.

Customizable: Available in various materials (e.g., stainless steel, carbon steel) and mesh sizes to meet specific filtration needs.

Efficient Filtration: Designed to trap particles while allowing fluid to pass through, improving filtration efficiency.

Common Uses

Industrial Filtration: Used in filter bags, strainers, and separators to remove contaminants from liquids and gases.

Water Treatment: Employed in water filtration systems to purify drinking water or wastewater.

Food and Beverage: Utilized in food processing to filter out solids from liquids, ensuring product quality.

Mining and Aggregates: Helps in the separation of materials during mineral processing.

Key Considerations

Mesh Size: Choosing the appropriate mesh size is crucial for effective filtration; smaller mesh captures finer particles.

Material Selection: Stainless steel is preferred for its corrosion resistance, while other materials may be used based on application requirements.

Maintenance: Regular cleaning may be necessary to ensure optimal performance and longevity of the mesh.