Silicon Carbide (SIC) Ceramic Foam Filter For Copper And Iron

Silicon Carbide (SIC) Ceramic Foam Filter produced by our company adopts imported raw materials from Germany and advanced laser cutting technology, which can meet the requirements of manual modeling and mechanized production line with higher efficiency, and ensure the quality standard requirements of casting factory productization.

Product Description

Silicon Carbide (SIC) Ceramic Foam Filter produced by our company adopts imported raw materials from Germany and advanced laser cutting technology, which can meet the requirements of manual modeling and mechanized production line with higher efficiency, and ensure the quality standard requirements of casting factory productization.

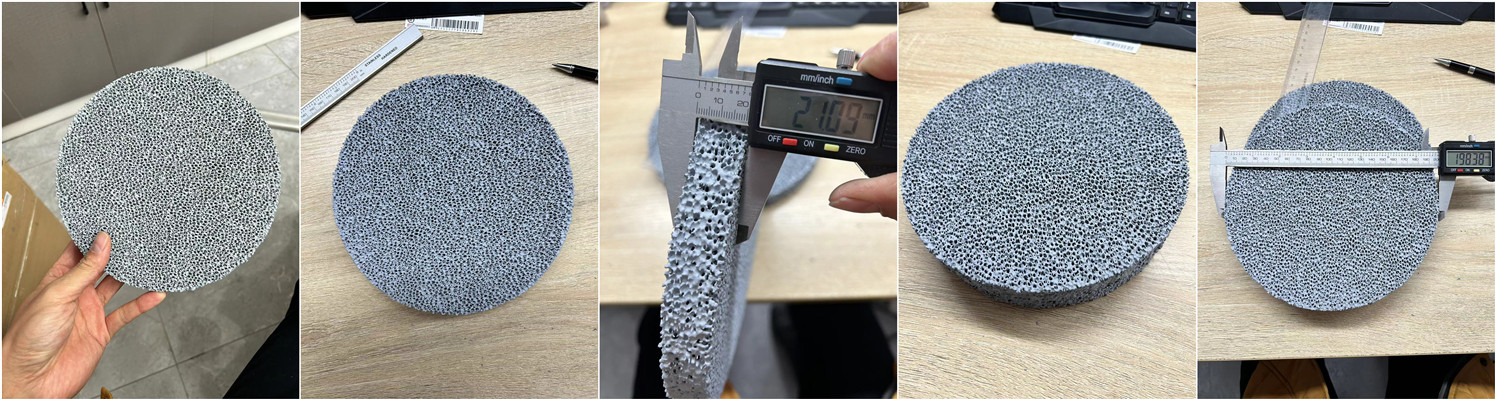

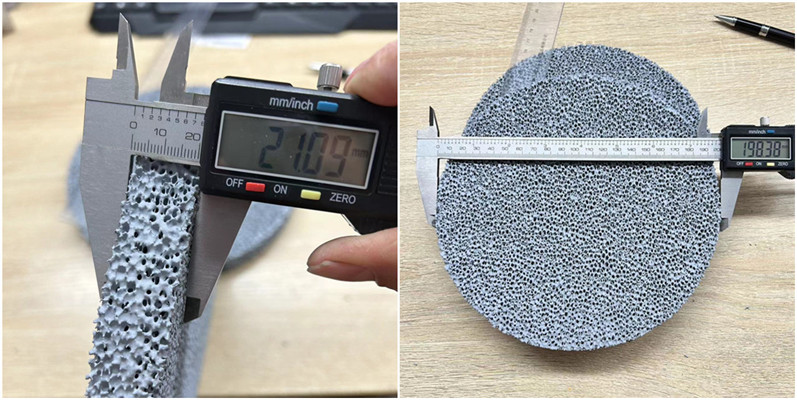

Excellent raw materials and advanced production technology ensure quite stable dimensional tolerance of our ceramic foam filters.

Due to the larger specific gravity of copper and alloys, including zinc alloys, greater thermal shock will be generated during casting. Therefore, in the process of copper casting, the size of the silicon carbide foam ceramic filter is generally strictly regulated.

What is especially valuable is that the life of copper castings purified by filtration is significantly prolonged in high requirements or harsh environment such as Marine turbine and chemical parts, and it also has good effect on the cast copper parts with surface polishing requirements.

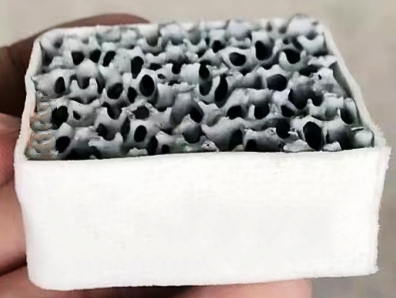

SIC (silicon carbide) ceramic foam filters with Paper Gasket

| Type | SIC ceramic foam filter for iron |

| Material | Silicon Carbide Powder |

| Work Temperature | ≤1500℃ |

| Color | Gray Black |

| PPI | 8/10/15/20/25/30PPI(PPI=pores per inch) |

| Porosity (%) | 80-90 |

| SiO2 (%) | 50-60 |

| Al2O3 (%) | 20-30 |

| MgO (%) | >10 |

| Compressive Strength (Mpa) | ≥2.0 (Room temperature) |

| Volume Density (g/cm3) | 0.36-0.5 |

| Bulk Density | 0.36-0.5g/cm3 |

| Soften Temperature (℃) | ≥1360 |

| Work Temperature (℃) | ≤1500 |

| Thermal Shock Resistance | 1200℃---room temperature 6 times |

| Certificate | ISO9001:2015 |

| REACH & RoHS |

| Spec./mm | Max.filter capacity/Kg | Normal flow of metal liquid Kg/s | ||

| Ductile Iron | Grey Cast Iron | Ductile Iron | Grey Cast Iron | |

| 30*50*22 | 30 | 60 | 3 | 4 |

| 40*40*22 | 32 | 64 | 3 | 4 |

| 50*50*22 | 50 | 100 | 4 | 6 |

| 75*50*22 | 75 | 150 | 6 | 9 |

| 100*50*22 | 100 | 200 | 8 | 12 |

| 75*75*22 | 110 | 220 | 9 | 14 |

| 100*75*22 | 150 | 300 | 12 | 18 |

| 100*100*22 | 200 | 400 | 16 | 24 |

| 150*100*22 | 300 | 600 | 24 | 36 |

| 150*150*22 | 450 | 900 | 36 | 54 |

| Φ40*11 | 20 | 40 | 2 | 3 |

| Φ50*22 | 35 | 70 | 3 | 4.5 |

| Φ60*22 | 50 | 100 | 4.2 | 6.5 |

| Φ70*22 | 75 | 150 | 5.5 | 8.8 |

| Φ80*22 | 100 | 200 | 7.2 | 11 |

| Φ90*22 | 120 | 240 | 9 | 14 |

| Φ100*22 | 140 | 280 | 11 | 17 |

| Φ150*22 | 350 | 700 | 25 | 38 |

Applications:

● SIC Ceramic foam filters can significantly improve the quality of cast iron parts and reduce the rejection rate. They can also be used in continuous casting and rolling processes and can be manufactured to different sizes and thicknesses depending on the runner and pouring weight.

● It can effectively remove oxidized inclusions and other non-metallic inclusions by blocking and capturing adsorption of molten copper or molten iron using three-dimensional structure. No matter gray iron, ductile iron, shaft body, cylinder block or complex large pieces, hardware parts after filtering, the quality will be very stable and satisfactory results.

● It is also suitable for copper, bronze, brass and other copper alloys, reduce the turbulence of copper liquid and purify the molten copper liquid. What is especially valuable is that the life of copper castings purified by filtration is significantly prolonged in high requirements or harsh environment such as Marine turbine and chemical parts, and it also has good effect on the cast copper parts with surface polishing requirements.

● It also plays an important role in the traditional copper industry, electrical and electronic copper industry and continuous casting and rolling technology. Since copper and its alloys, including zinc alloys, have greater specific gravity and produce greater thermal shock during pouring, the use of silicon carbide foam ceramic filters in the copper casting process generally has strict size requirements.

Production Process:

Quality Inspection:

Three most important key points that make our quality always best are:

● The most advanced testing equipment and technology are adopted today in Hebei Cangchen to ensure the consistant filters quality.

● There is a quality inspection team with rich experience and technology to keep best quality in our quality control department.

● Thanks to many years of product export and feedback information from domestic and foreign customers, we have accumulated considerable experience and expertise in quality control and improvement.

For now, Hebei Cangchen is a professional manufacturer with ISO certificate and our Silicon Carbide (SIC) ceramic foam filters have been passed RoHS And Reach test and certified.