900mm Width(Wave-type) Roofing Sheet

900mm Width(Wave-type) Roofing Sheet

Product Description

Galvalume metal roofing sheet is a kind of building material. It is formed with galvalume coil, which is a kind of steel coated with a mixture of 55% aluminum, 43.4% zinc, and 1.6% silicone through the hot-dip galvalume process. The aluminum-zinc alloy protects the base steel against corrosion and rust. galvalume metal sheets have many features, such as high heat resistance, superior corrosion resistance, excellent formability, high reflectivity, etc. So it is suitable for extreme environments.

Galvalume Metal Sheets Specifications

♦ Model No.: Wavy Type YY18-76-900

♦ Thickness: 0.14-0.4mm

♦ Wave: 12

♦ Height: 18mm

♦ Width Before Corrugation: 1000mm

♦ Width After Corrugation: 900mm

♦ Length:3050mm or As Your Required.(for 20'gp,less than 5800mm)

♦ Material: Galvanized Steel Sheet, Galvalume Steel Sheet, PPGI/PPGL steel coil

♦ PPGI Color: According to RAL color or samples

Colors of Galvalume Metal Roof

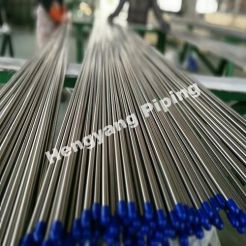

the GL steel is silver in color. It looks not as shiny as galvanized steel. But its spangles will be more even and uniform. If you want a colorful roofing sheet, you can choose PPGI or PPGL roofing sheets. Below are two pictures of GI and galvalume metal roof panels for your reference.

Benefits of Galvalume Roofing Sheet

1. Superior Corrosion Resistance

The aluminum layer offers galvalume steel excellent corrosion resistance. When the zinc is worn away, the aluminum forms a dense layer of aluminum oxide, preventing corrosion-resistant substances from further corroding the interior. So the corrosion resistance of galvalume flat sheets is 3 times that of galvanized sheet. The service life of GL roofing sheet is 2-6 times that of GI roofing sheet under the same circumstances.

2. High Heat Reflectivity

Its reflection coefficient is twice that of galvanized metal roofing sheet, which can reduce the indoor temperature in summer and reduce the power consumption of air conditioner. This feature makes it perfect for hot climates.

3. High-temperature Resistance

GL roofing sheet has good heat resistance and can withstand high temperatures of more than 300 degrees. Therefore, it can be used for a long time at high temperatures.

4. Smooth Surface & Uniform Appearance

Galvalume roofing sheet is smooth, silvery-white in color with uniform spangles. It looks beautiful and can be used directly. Hence, it is widely used in commercial and residential uses.

5. Great Formability & Adhesion

The adhesion between GL coating and paint is good, which makes it easy to paint. Also, galvalume metal sheets have great formability, easy to stamp, cut, etc.

These features of galvalume roofing sheets make it popular in many projects. At JINBOWANTONG Steel, we promise to offer you quality roofing sheets. Besides, third party quality inspection is acceptable. So no matter where you will use the roofing sheets, you can try GL roofing panels.

Galvalume Roofing Sheet VS Galvanized Sheet

These two metal roofing sheets are widely used. They are used for a variety of similar applications, but their features significantly differ. Below are more details.

1. Different Materials

Galvalume sheet is coated with aluminum and zinc alloys (55% aluminum, 43.4% zinc, and 1.6% silicone), while galvanized steel is covered with pure zinc coating. For roofing sheets or floor decks (outdoor uses), the zinc layer of galvanized sheets is more than 275 g/㎡ (Z27), and 350 g/㎡ (Z35) for the coastal areas. However, if you use galvalume steel it should be more than 100 g/㎡(AZ100) and 185 g/㎡(AZ185) for floor decks.

2. Corrosion Resistance

The aluminum naturally resists corrosion to better protect the steel core against corrosion compared to galvanized sheets. The corrosion resistance of Al-Zn coating can last more than 50 years. It is proven that the service life of galvalume roof panels will last more than 50 years, which is 20-30 years longer than that of GI roofing sheets. However, less zinc content makes anodic protection greatly reduced. That is, once the galvalume sheet is cut, the cut edge will rust quickly. So cut the GL metal as little as possible during installation. And remember to paint a layer of coating on the cut edge to prolong the service life of your roofing sheet.

3. Heat Reflectivity

The thermal reflectivity of galvalume metal is very high, twice that of GI sheet. Therefore, as roofing sheets, GL sheets will be more suitable for the hot climate.

4. Surface

The surface of GL sheet is smooth, with even spangles. The base color is silver-white. While GI sheet is shinier, and its spangles are not even. Below are pictures for your reference.