GPPS General Purpose Polystyrene

GPPS plastic, short for General Purpose Polystyrene, is a widely used thermoplastic material known for its versatility, transparency, and affordability. It finds extensive applications in various industries, ranging from packaging to consumer goods and electronics.

Product Description

GPPS Plastic Material: An Overview

GPPS plastic, short for General Purpose Polystyrene, is a widely used thermoplastic material known for its versatility, transparency, and affordability. It finds extensive applications in various industries, ranging from packaging to consumer goods and electronics. In this article, we will delve into the properties, applications, advantages, limitations, and future prospects of GPPS plastic, shedding light on its unique characteristics and considerations for its usage.

Introduction to GPPS Plastic Material

GPPS plastic, a type of polystyrene, is derived from styrene monomers through a polymerization process. It is a rigid and transparent material with excellent clarity, making it suitable for applications where visual aesthetics are essential. Due to its desirable properties, GPPS plastic has gained popularity in several industries. As an experienced Plastic Raw Materials manufacturer, we sell the best and various plastic materials. If you are interested in our GPPS Plastic Material, feel free to contact us!

What is GPPS Plastic?

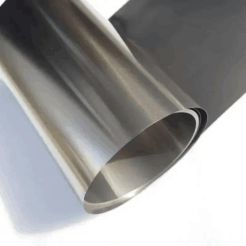

GPPS plastic is a thermoplastic material that possesses high rigidity and clarity. It is commonly available in the form of pellets or granules, which can be easily processed and molded into different shapes using techniques like injection molding and extrusion. GPPS plastic is manufactured through a process called suspension polymerization, resulting in a homogenous material with uniform properties.

Properties and Characteristics of GPPS Plastic

1. Transparency and Clarity

One of the notable features of GPPS plastic is its exceptional transparency and clarity. This material allows high light transmission, making it ideal for applications that require visibility or showcasing products. The optical properties of GPPS plastic are comparable to glass, but it is much lighter and less fragile.

2. Rigidity and Strength

GPPS plastic exhibits high rigidity and stiffness, providing structural integrity to the manufactured products. It maintains its shape under normal operating conditions and can withstand moderate mechanical stress. However, it is important to note that GPPS plastic is relatively brittle compared to some other plastics.

3. Lightweight and Versatile

Despite its rigidity, GPPS plastic is lightweight, offering ease of handling and transportation. Its versatility enables it to be shaped into various forms, making it suitable for different applications. The ease of processing and compatibility with a range of manufacturing techniques contribute to its widespread usage.

Details

|

Item |

Test conditions |

Test method |

Test data |

unit |

|

Density |

|

ISO 1183:1987 |

1040 |

kg/m3 |

|

Water absorption |

|

ISO 62:1999 |

<0.1 |

% |

|

Melt flow rate |

200°C/5kg |

ISO 1133:1997 |

3.8 |

cm3/10min |

|

Process shrinkage |

|

ISO 294-4:1997 |

0.4-0.6 |

% |

|

Charpy impact strength |

1eU |

ISO 179:1993 |

15 |

kj/m2 |

|

Tensile modulus |

1mm/min |

ISO 527-2:1993 |

3300 |

MPa |

|

Elongation |

50mm/min |

ISO 527-2:1993 |

3 |

% |

|

Tensile strength at break |

50mm/min |

ISO 527-2:1993 |

55 |

MPa |

|

Ball indentation hardness H |

358N/30s |

ISO 2039-1:1993 |

150 |

N/mm2 |

|

Bending strength |

2mm/min |

ISO 178:1993 |

100 |

MPa |

|

HDT |

1.8MPa |

ISO 75-2:1993 |

84 |

°C |

|

Linear coefficient of thermal expansion |

(23-80)°C |

DIN 53 752 |

0.8-1.0 |

K-1 |

|

Heat conduction |

|

DIN 52 612 |

0.16 |

W/mK |

|

Vicat softening point |

B50/oil |

ISO 306:1994 |

93 |

°C |

|

Flame retardance |

>1.4mm |

UL-Standard 94 |

94HB |

Class |

Applications of GPPS Plastic

GPPS plastichas a broad range of applications across multiple industries, the major industries that use GPPS plastic include:

1. Packaging Industry

GPPS plastic is commonly used in the packaging industry for producing containers, lids, trays, and other products that require high transparency and visual appeal. Its ability to retain the freshness and flavor of food products makes it a popular choice for food packaging.

2. Consumer Goods

GPPS plastic finds extensive applications in the manufacturing of consumer goods such as toys, office supplies, and household items. Its ability to retain colors and designs makes it an ideal material for producing decorative items and novelties.

3. Electronics

The electronics industry also uses GPPS plastic for manufacturing computer and electronic components, including housings, bezels, and display screens. Its transparency and clarity make it an excellent material for producing light diffusers, LED lenses, and backlighting components.

4. Automotive Industry

GPPS plastic is also used in the automotive industry for producing various interior and exterior components such as instrument panels, dashboards, and exterior trim parts. Its lightweight and low cost make it a suitable alternative to metal and other heavier materials.

Advantages of GPPS Plastic

GPPS plastic offers several advantages over other materials, making it a popular choice for various applications. Some of the key benefits of GPPS plastic include:

1. Cost-Effective

GPPS plastic is a cost-effective material, making it an ideal choice for applications where affordability is a primary consideration. It is one of the most affordable plastics available, making it an excellent alternative to more expensive materials like acrylic.

2. Easy Processing and Molding

GPPS plastic is easy to process and mold, allowing manufacturers to produce complex shapes and designs with ease. Its compatibility with various processing techniques like injection molding, blow molding, and thermoforming makes it a versatile material for different applications.

3. Recyclable and Sustainable

GPPS plastic is fully recyclable, making it an environmentally friendly material. It can be reprocessed into new products without losing its properties, reducing waste and conserving resources.

Comparisons with Other Plastic Materials

GPPS plastic is often compared to other plastic materials with similar properties to determine the most suitable material for a specific application. Some of the common comparisons include:

GPPS vs. HIPS

GPPS and HIPS (High Impact Polystyrene) are both derived from styrene monomers but have different properties. HIPS is modified with rubber to increase its impact resistance, making it more suitable for applications that require durability and toughness.

GPPS vs. ABS

GPPS and ABS (Acrylonitrile Butadiene Styrene) have similar properties but differ in terms of impact resistance and processing. ABS is more impact-resistant than GPPS and can be processed using a wider range of techniques, making it suitable for more demanding applications.

GPPS vs. PET

GPPS and PET (Polyethylene Terephthalate) are both transparent plastics, but they have different properties and applications. PET is known for its excellent mechanical strength, chemical resistance, and ability to withstand high temperatures, making it a preferred choice for beverage bottles and food containers.

Tips for Working with GPPS Plastic

To ensure successful use of GPPS plastic in manufacturing processes, consider the following tips:

1. Storage and Handling

Store GPPS plastic in a cool and dry environment to prevent moisture absorption, which can affect its properties. Handle the material with care to avoid excessive stress or impact that may lead to breakage.

2. Processing Techniques

When processing GPPS plastic, ensure that the machine parameters, such as temperature and injection pressure, are set correctly. Optimize the processing conditions to achieve the desired quality and avoid issues like surface defects or dimensional inconsistencies.

Frequently Asked Questions (FAQs)

1. Is GPPS plastic safe for food packaging?

GPPS plastic is generally considered safe for food packaging as it meets regulatory standards. However, it is important to ensure that specific food-grade GPPS materials are used for direct food contact applications.

2. Can GPPS plastic be recycled?

Yes, GPPS plastic is recyclable. It can be processed and reprocessed into new products, reducing waste and promoting sustainability.

3. How does GPPS plastic compare to acrylic?

GPPS plastic and acrylic have similar transparency properties, but acrylic is more durable and has better impact resistance. Acrylic is often preferred for applications that require higher performance and longevity.

4. What are the temperature limitations of GPPS plastic?

GPPS plastic has limited resistance to high temperatures and may deform or soften at elevated temperatures. It is recommended to use it within its specified temperature range to maintain its integrity.

We look forward to working with you!

At Hebei ChaoKe Import and Export Co., Ltd., we understand that in today's rapidly evolving industries, the choice of materials can make all the difference. That's why we are excited to introduce our high-quality General Purpose Polystyrene (GPPS) plastic material, designed to meet the diverse needs of manufacturers across various sectors. With our extensive experience in the chemical trade, robust supply chain solutions, and commitment to customer satisfaction, we aim to become your trusted partner in delivering top-notch GPPS plastic materials.

Embrace the advantages of GPPS plastic material from ChaoKe and unlock the potential for innovation and growth in your manufacturing processes. With our top-quality GPPS plastic, extensive industry expertise, robust supply chain solutions, and unwavering commitment to customer satisfaction, we are poised to be your trusted partner in delivering exceptional chemical solutions. Contact us today to explore the possibilities and take your business to new heights.