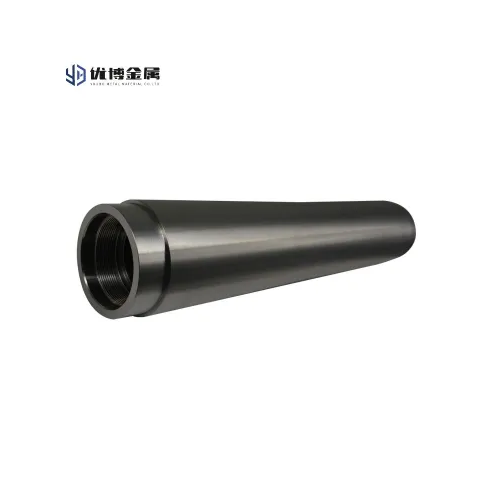

Tungsten Tube & Pipe

Tungsten tubes are commonly used in high-power radio transmitters and other applications where high power and high frequency are required. They are also used in some types of light bulbs and other electronic devices.One advantage of tungsten tubes is their ability to operate at high temperatures without breaking down or losing efficiency.

Product Description

A tungsten tube, also called a tungsten pipe, is a type of cylinder-shaped tube made from the chemical element tungsten. Due to the unique physical and chemical properties, tungsten tubes are used for a wide range of applications like producing filaments, sputtering targets and heating elements. Tubes are available in various sizes that are manufactured as per the requirements.

Tungsten tubes are obtained from rods through a process that involves isotactic pressing, sintering, machining and finishing. Usually, the tungsten tubes use more than 90% pure tungsten therefore retaining the metal’s superior qualities, such as high purity, corrosion resistance, high density, and robustness. Tungsten tubes are generally polished so the surface inside and outside the tube is even without any cracks.

Tungsten Tube Parameter:

|

Purity |

99.95% |

|

Density |

19.2cm³/g |

|

Melting point |

3400℃ |

|

Boiling point |

5972℃ |

|

Grade |

W-1 |

|

National standard |

YS/T 796-2012 |

|

American standard |

|

|

Surface |

Electrolytic polishing |

Luoyang Youbo supplies high-quality Tungsten Tube / Tungsten Pipe at a competitive price. Request a free quote.

Tungsten Tube Key Features:

• High melting point (3410 °C)

• Low thermal expansion

• High electrical resistance

• Low vapour pressure

• High density

• Resistance to oxidation and creep

• Extreme hardness

• High tensile strength

Tungsten Tube Applications:

Tungsten tubes are really strong and durable. They are used in many different industries because of their exceptional strength and durability:

• Thermocouple sheaths

• Semiconductors

• Electronic controls

• Medical devices

• Nuclear

• Aerospace critical applications

• Advanced electronics

• Solar thermal management technologies

• High-temperature furnace parts applications

• To make filaments

• For automotive parts

• To make sputtering targets

• For sapphire crystal growth furnace

• For smelting rare earth metals

• For furnace heating elements

• Making sapphire crystals

• Melting rare earth metals

• Heating elements in furnaces

• Making quartz glass

• Tungsten tubes are also used more and more in the LED industry.

Production technology:

The production process is as below: Isostatic pressure - intermediate frequency sintering - machining - tungsten tube finished product

Tungsten Tube Supplier - Youbo's Advantages

Looking for a reliable supplier of tungsten tubes? Your search ends with Youbo. We provide custom-made tungsten tubes and tungsten pipes for high-temperature applications. , with strict quality control and on-time delivery. Our products are designed with precision and tailored specifications to meet your specific needs.

With years of experience, we cater to diverse industry requirements. Choose Youbo for quality, expertise, and reliability. Our tungsten tubes offer high purity, density, strength, and erosion resistance. The polished surface ensures a smooth, crack-free inside and outside wall.

We also provide Tungsten Crucibles, Tungsten Boats, Tungsten Electrodes, Tungsten Cubes, Tungsten Pipes, Tungsten Powder, Tungsten Circles, Tungsten Sheets and Plates, Tungsten Balls, Tungsten Wires, Tungsten Rods and Bars, and Tungsten substrates.

Packing, transportation and storage:

The Tungsten Tubes are packed into wooden cases with shockproof and moisture-proof materials, and the wooden cases are packed tightly with soft materials. Tungsten Tubes are not packed in wooden cases, need to be wrapped in soft plastic paper, and then fixed on a strong support frame, to ensure the stability of the product.

Tungsten Tubes in transportation should pay attention to shock-proof, moisture-proof, pressure-proof, and prevent secondary pollution.

If the demander has special requirements on the marking, packaging, transportation and storage of the products, both parties shall negotiate.