0Cr25Al5 FeCrAl Alloy

FeCrAl alloy materials are resistant to creep over a wide range of temperatures. Fecral 255 alloy have several advantages such as lower raw material cost, superior oxidation resistance, lower density, and lower coefficient of thermal expansion than nicr alloys.

Product Description

FeCrAl alloy materials are resistant to creep over a wide range of temperatures. Fecral 255 alloy have several advantages such as lower raw material cost, superior oxidation resistance, lower density, and lower coefficient of thermal expansion than nicr alloys. However, fecral wire has lower strength than nicr alloys, after heating, the ductility of the alloy becomes poor, easy brittleness, not easy to weld.

0Cr25Al5 resistance alloy is composed of iron chromium aluminum, which has high resistivity, low temperature coeffcient of electric resistance,high working temperature, good oxidation resistance at high temperature, and the maximum applicable temperature is as high as 1250 degrees.

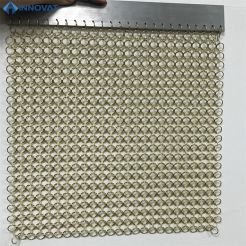

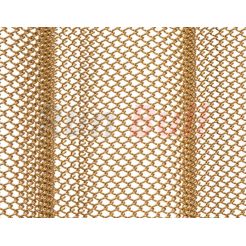

ocr25al5 is mainly used in the production of ceramic electric cooking utensils, industrial furnaces, and various electric heating elements.We mainly produce ocr25al5 alloy heating wire,fecral 25/5 strip,0cr25al5 fecral alloy foil,fecral heating resistance ribbon,fecral wire mesh,etc.

Chemical composition%

|

C |

P |

S |

Mn |

Si |

Cr |

Ni |

Al |

Fe |

Other |

|

Max |

|||||||||

|

0.06 |

0.025 |

0.025 |

0.70 |

Max 0.60 |

23.0~26.0 |

Max 0.60 |

4.5~6.5 |

Bal. |

- |

Mechanical properties (1.0mm)

|

Yield Strength |

Tensile Strength |

Elongation |

|

Mpa |

Mpa |

% |

|

500 |

700 |

23 |

Physical properties

|

Density(g/cm3) |

7.10 |

|

Resistivity at 20°C(Ωmm2/m) |

1.42 |

|

Thermal conductivity at 20°C (WmK) |

13 |

|

Thermal expansion coefficient |

|

|

Temperature |

Average Linear Expansion Coefficient x10-6/℃ |

|

20 ℃- 1000℃ |

15 |

|

Specific heat capacity |

|

|

Temperature |

20℃ |

|

J/gK |

0.46 |

|

Melting point (℃) |

1500 |

|

Maximum operating temperature of components(℃) |

1250 |

|

Magnetic |

Magnetic |

Resistance temperature factor (correction factor)

|

20℃ |

100℃ |

200℃ |

300℃ |

400℃ |

500℃ |

600℃ |

700℃ |

800℃ |

900℃ |

1000℃ |

1100℃ |

1200℃ |

1300℃ |

|

1 |

1.002 |

1.005 |

1.008 |

1.013 |

1.021 |

1.030 |

1.038 |

1.040 |

1.042 |

1.044 |

1.046 |

1.047 |

|

Supply form and specification

|

Alloy grade |

Form |

Specification |

|

|

0Cr25Al5 |

Wire |

Diameter=0.1mm~8mm |

|

|

0Cr25Al5 |

Flat wire |

Width=1~5mm |

Thick=0.1~1.5mm |

|

0Cr25Al5 |

Strip |

width=5~250mm |

ThickT=0.1~3.0mm |

|

0Cr25Al5 |

Foil |

width=6~120mm |

Thick=0.05~0.1mm |

|

0Cr25Al5 |

Bar |

Diameter=5~100mm |

Long=50~1000 |

We provide customized services, and the size and packaging of products can be customized according to customer needs. The production of our fecral alloy products strictly follows the national standards. If customers have special requirements, we can also produce according to the national standards of customers.