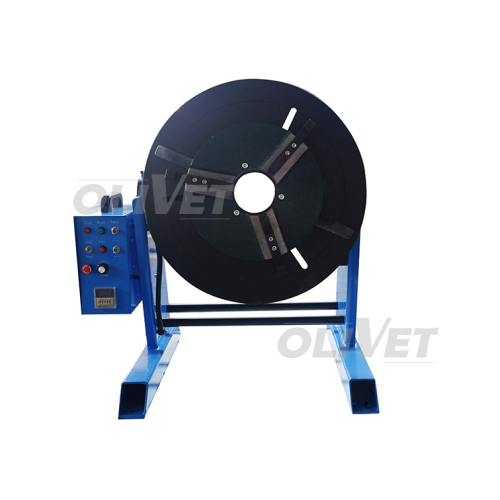

Pipe Welding Positioner

Pipe positioners are devices that are used to hold and position pipes while they are being welded. Olivet's HBJ-S Series light duty welding positioners are with capacities ranging for 100 to 300kg. Customized options for different requirements are accepted!

Product Description

Pipe Welding Positioner - HBJ- S Series

Pratical and Versatile - Recognized by customers in Europe and the United States

Olivet has a comprehensive range of positioner for automatic welding. These very versatile handling tools enable welding to be carried out in the optimum positions to benefit the quality of the work. Olivet's HBJ-S Series light duty welding positioners are with capacities ranging for 100 to 300kg. (Meets most European and U.S. customer requirements for lightweight welding positioners.)

The pipe welding positioner is a device that rotates around 360°, allowing the welder to stand in one position and continuously perform pipe welding work on a horizontal surface. It adds comfort for welders who must work on shaped parts, such as tubular pipe. pipe welding positioner prevents worker fatigue and increases productivity because workers do not have the movement necessary to complete the welded pipe work. Since no overhead or vertical runs are involved, this method also tends to provide consistently high quality welds.

Pipe positioners are typically used in conjunction with a welding positioner, which is a piece of equipment that rotates and tilts the workpiece to the desired position. The combination of the pipe positioner and the welding positioner allows the welder to easily position the pipe for welding, improving the accuracy and quality of the weld. Pipe positioners are commonly used in the manufacturing of pipelines, boilers, and other piping systems where it is important to achieve precise, high-quality welds.

Pipe Welding Positioner Design Features

For annular welding, cutting, polishing and assembly.

Easy to set up a small welding center equipped with quick chuck, torch holder and roller supports.

DC infinitely variable speed control system..

Time relay is equipped for auto welding.

Kinds of extended devices, torch holder and pneumatic cone for choose.

High frequency protection on electric box.

Compact and robust design, easy to operate.

Scope of Delivery

A. 1 Body

B. 1 electric box & 1 control foot switch

Pipe Welding Positioner Main Technical Parameters

|

Model |

Horizontal load |

Vertical Load |

Rotation speed |

Tilting range |

Table dia. |

Table center hole |

|

HBJ-S50 |

50kg |

30kg |

1-10 rpm |

0 º-90 º/ manual |

Ø400 mm |

Ø25mm |

|

HBJ-S100 |

100kg |

50kg |

0.5-5 rpm |

0 º-90 º/ manual |

Ø400 mm |

Ø45mm |

|

HBJ-S200 |

200kg |

100kg |

0.5-5 rpm |

0º -90º/ manual |

Ø400mm |

Ø45mm |

|

HBJ-S300 |

300kg |

150kg |

0.2-2.5 rpm |

0º-90º/ manual |

Ø500mm |

Ø90mm |

If the pipe welding positioner parameters you need are not found, please ask us any questions about your needs. The important thing is that we are a physical factory and we accept custom orders! This is a better price and better after-sales guarantee than some big-name distributors!

Rich Extended devices

1. Quick Chuck

|

Model |

Load/ clamp capacity |

Inner dia. of clamp |

Outer dia. of clamp |

Clamping range with add. jaws |

|

WP200 |

30 kg/ 200 kg |

Ø110-210 mm |

Ø20-130 mm |

Ø5-300 mm |

|

WP300 |

120 kg/ 250 kg |

Ø170-280 mm |

Ø80-190 mm |

Ø10-400 mm |

|

WP400 |

240 kg/ 350kg |

Ø250-380 mm |

Ø120-250 mm |

Ø20-500 mm |

2. Stand torch holder assembly

|

Model |

Vertical stroke |

Horizontal stroke |

|

TH-001 |

1000mm |

500mm |

3. Manual torch and manual pneumatic cone assembly

|

No |

Item |

Parameter |

|

1 |

Torch holder |

3 axis adjusting |

|

2 |

Pneumatic cone |

Airtac pneumatic cylinder with manual valve |

|

3 |

Aluminium track |

European standard 1500m |

Advantages of Pipe Positioners in Welding

Enhanced Productivity

By automating the rotation and tilting of the workpiece, pipe positioners reduce the need for manual adjustments by welders. This streamlines the welding process, increasing productivity and allowing welders to focus on the quality of their work.

Improved Weld Quality

Pipe positioners ensure consistent and accurate welds by maintaining a steady and controlled position throughout the welding process. This eliminates inconsistencies and reduces the likelihood of defects, resulting in superior weld quality.

Operator Safety

Welding can be a physically demanding and hazardous task, especially when dealing with heavy or awkwardly positioned pipes. Pipe positioners minimize the risk of injuries to welders by providing a safer and more ergonomic working environment.

Versatility in Welding Applications

Pipe positioners are highly versatile and can be used in various welding applications, including:

Fillet Welding

Fillet welding requires precision and accuracy, which can be easily achieved using a rotating pipe positioner.

Circumferential Welding

Rotating pipe positioners are the perfect choice for circumferential welding, ensuring uniformity and consistency along the pipe's circumference.

Longitudinal Welding

For longitudinal welding, tilting positioners allow for easy access to the weld joint and smooth travel of the welding torch.

Weld Positioner Options

OLIVTE offers several unique styles of new weld positioners to meet your project needs. Listed below are some of the unique welding positioner styles we carry.

Benchtop welding positioners offer excellent workpiece positioning within a small frame design that can be easily mounted on a table or desktop. Our new and used benchtop weld positioners offer part rotation and tilt capabilities for precise workpiece positioning.

Rotating weld turntables offer the key advantage of precise positioning in a flat or horizontal position. They also provide a highly accurate, cost-effective method of rotating pipes, vessels or industrial workpieces around a vertical axis. Floor turntables are used primarily for welding, flame cutting, x-ray and machining applications.

Pipe welding indexers greatly increase productivity when welding pipes, shafts, wheels, elbows and other fittings. Together with a welding turntable, pipe welding positioners are especially useful when rotating or positioning workpieces with large offset loads. Pipe welding positioners are used in a variety of applications, from pipe winding to positioning very large and bulky parts, such as chassis components or structural steel.

Rotary welding positioners make it easier and more efficient to weld round objects. A reversible variable speed control box allows you to dial in exactly the right speed, while an optional variable speed pedal adds another level of control. These weld positioners are useful for precision welding applications.

Headstock and Tailstock Positioners

Our new head and tailstock weld positioners are designed for long rectangular shapes that must be supported from both ends. Fixed height swivel, centerline and power lift models are available for ergonomic weld part placement. Headstock tailstock positioners also allow for maximum flexibility when lifting or rotating heavy workpieces such as trailer frames or large vessels.

Fixture welding chucks are specialized fixtures designed to withstand the harsh conditions of the welding industry. They are primarily used to hold custom metal parts that are fixed to the spindle box/tailstock and can therefore be welded. Our chuck welding rental equipment is a cost effective way to increase your welding capabilities and efficiency. We offer the highest quality equipment at an affordable price.

Universal weld positioners use a variety of methods to hold and position the part for welding, allowing the part to rotate or pivot a full 360° so the welder can stay in one position on a safe, flat surface. General welding positioners are those that do not fall into one of the major welding positioner categories.

If you are interested in Pipe welding positioner, please read more or contact us.

OLIVTE manufactures pipe welding positioners that provide a higher level of comfort for welders, thereby improving welding accuracy on complex jobs. Welding positioners increase productivity and offer a wide range of features, from basic functions to more advanced positioning applications.

How does the Pipe Weld Positioner work?

The Pipe Weld Positioner operates efficiently by gripping the pipe joint or valve and rotating the workpiece as needed, so the welder can continuously weld the pipe joint in a flat position without interruption in the process. This allows the welder to keep the weld pool in the pipe joint without having to manipulate the torch or weld clamp.

Pipe weld positioners are practical for improving weld deposition rates and reducing scrap rates because they allow better access to the weld on the pipe. Welding fixtures or weld positioners help operators weld at a faster rate than manual or semi-automatic weld setups.

How do I properly use a Pipe weld positioner?

Safety is always a top priority when operating a Pipe weld positioner. - It is important to ensure that your Pipe welding positioner is always fixed on a flat, stable surface. The tabletop Pipe welding positioner should also be secured.

It is also important to check the manufacturer's specifications of the Pipe welding positioner. - The motor and controls depend on the size and speed required for the welder to perform, and the manufacturer's specifications will tell you if the welding positioner can handle the operation you need to perform.

A ground current should also be connected to the positioner during the welding process. - Without it, electrical components may be damaged. You should also make sure that the positioner is compatible with the current generated by the welding process.

FAQs

What is the purpose of a pipe positioner in welding?

A pipe positioner is used to manipulate the orientation of pipes during welding, allowing for better access and precise welds.

What are the different types of pipe positioners available?

Common types include rotating, tilting, and headstock and tailstock positioners.

How do pipe positioners enhance welding productivity?

Pipe positioners automate the rotation and tilting of the workpiece, reducing manual adjustments and streamlining the welding process.

Can pipe positioners be used for different types of welding?

Yes, pipe positioners are highly versatile and can be used for fillet welding, circumferential welding, and longitudinal welding.

What factors should be considered when selecting a pipe positioner?

Weight capacity, rotational speed, torque, and automation features are essential considerations when choosing a pipe positioner for specific welding requirements.

Articles that may be helpful to you

Technical characteristics of rotating type welding positioner