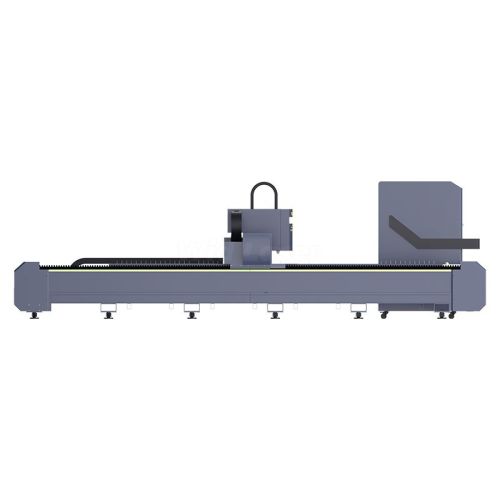

5000W Metal Sheet Laser Cutter

Product Description

https://www.wid-laser.com/productstags/5000w-metal-sheet-laser-cutter.html

Title: 5000W Metal Sheet Laser Cutter: Revolutionizing Precision Manufacturing

In the dynamic world of precision manufacturing, technological advancements continue to push the boundaries of efficiency and accuracy. One such innovation that has taken the industry by storm is the 5000W Metal Sheet Laser Cutter. This cutting-edge machinery has revolutionized the way metal sheets are processed, offering unprecedented precision, speed, and versatility.

The Power of 5000W Metal Sheet Laser Cutter

The 5000W Metal Sheet Laser Cutter stands as a testament to human ingenuity and engineering prowess. This cutting-edge equipment harnesses the power of a 5000-watt laser to slice through metal sheets with astonishing accuracy. It employs advanced optics and cutting-edge control systems to deliver precise cuts, significantly reducing material wastage and production costs.

Unparalleled Precision

The cornerstone of the 5000W Metal Sheet Laser Cutter's success lies in its unparalleled precision. The intense laser beam focuses on a minute spot on the metal surface, melting and vaporizing the material with a minimal heat-affected zone (HAZ). This results in clean, sharp cuts, and enables manufacturers to achieve intricate designs and geometries that were previously unattainable through traditional cutting methods.

Versatility at Its Best

Unlike conventional cutting techniques that are limited in their applications, the 5000W Metal Sheet Laser Cutter boasts remarkable versatility. It can effortlessly handle a wide range of materials, including stainless steel, aluminum, brass, copper, and more. Moreover, this cutting-edge machine can process varying material thicknesses, making it an ideal choice for diverse industrial sectors.

Enhanced Productivity

In an era where time is of the essence, the 5000W Metal Sheet Laser Cutter outperforms traditional cutting methods by a significant margin. The laser's incredible speed and accuracy allow for rapid processing of metal sheets, translating to enhanced productivity and quicker turnaround times. As a result, manufacturers can meet demanding project deadlines while maintaining optimal quality.

Reduced Material Waste

Material wastage is a pressing concern for manufacturers, both in terms of cost and environmental impact. The 5000W Metal Sheet Laser Cutter addresses this issue with its precise cutting capabilities. By minimizing the width of the cut and maximizing material utilization, this technology greatly reduces scrap material, leading to a more sustainable manufacturing process.

Applications Across Industries

The applications of the 5000W Metal Sheet Laser Cutter span numerous industries, from automotive and aerospace to electronics and architecture. In automotive manufacturing, the machine plays a pivotal role in creating intricate parts and components with exacting tolerances. In the aerospace sector, it aids in producing lightweight yet robust structures critical for aircraft performance. Moreover, in the electronics industry, the laser cutter enables the fabrication of precise circuit boards, ensuring seamless functionality.

Safety and Automation

Safety is of paramount importance in any manufacturing environment, and the 5000W Metal Sheet Laser Cutter does not fall short in this aspect. Equipped with advanced safety features, such as automatic shutdown protocols and protective enclosures, it mitigates potential hazards and ensures a secure working environment.

Additionally, many modern laser cutters come with automation features, including computer numerical control (CNC) integration. This allows for precise and repeatable cuts, reducing the need for manual intervention and further enhancing overall efficiency.

Conclusion

The 5000W Metal Sheet Laser Cutter has undoubtedly changed the landscape of precision manufacturing. With its unmatched precision, versatility, and productivity, this cutting-edge machinery continues to drive innovation across industries. As technology evolves, we can expect even more groundbreaking developments in laser cutting, solidifying its place as a cornerstone of modern manufacturing processes. Embracing this technology not only propels businesses forward but also paves the way toward a more sustainable and precise future.