Cement Columns for Protective Fences

HPB300 cold-drawn low-carbon steel wire and Q235 rectangular tube frame are used internally; after welding, the surface is treated with overall hot-dip galvanizing and then plastic dipping.

Product Description

Protective fences

Reinforced concrete column metal mesh protective fences are composed of columns, mesh and connecting parts, with a protective height of 1.8m. According to national requirements, Anping County Dishun Wire Mesh Co., Ltd. specializes in producing two national standard products, Tongxian 2012-8001 and Tongxian 2012-8002, to provide safety protection for railway lines.

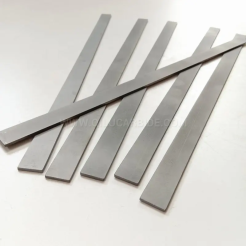

Product material and process: HPB300 cold-drawn low-carbon steel wire and Q235 rectangular tube frame are used internally; after welding, the surface is treated with overall hot-dip galvanizing and then plastic dipping. The plastic dipping powder generally adopts dark green, smooth and flat surface, long-term corrosion resistance and UV resistance. Railway protective fences are safety facility installation projects for railways, mainly used on both sides of railway tracks to prevent pedestrians from approaching the tracks and trains to ensure the personal safety of pedestrians. Therefore, railway protective fences are more stringent than other isolation fences in terms of technology and quality. Railway protective fences use column concrete castings, which have low engineering cost, high strength, good overall stability, and are suitable for large-scale use.

Common specifications of railway protective fences are as follows:

Mesh (mm): 75x150

Mesh (mm): 1797x2760

Frame (mm): 30x50x2.0

Mesh wire plastic dipping (mm): 0.7-0.8

Mesh wire after plastic (mm): 4.8-5.0

Resistance welding should be used for welding the steel wire of the protective fence and the rectangular frame. If brazing is used, suitable welding rods should be used to minimize deformation. Clean the welding slag after welding. The deformation caused by welding should be leveled. To ensure that the mesh itself has sufficient strength, the strength of the mesh wire welding point is greater than 1000N, and the number of welding point shedding is less than 4%. The protective fence metal mesh is installed on the inside of the concrete fence. Use 10mm diameter and 150mm long expansion screws to drill holes along the center of the column and the upper and lower sills. The hole depth is not less than 50mm. Fix the metal mesh, and then add anti-theft caps to each expansion screw and tighten it with nuts. The spacing of the expansion screws is 300mm.

Installation method steps:

1.1 First, use M10*142mm bolts to pass through the reserved holes on the concrete column, and use matching anti-theft washers and nuts to fix the two connecting plates A on both sides of the concrete column;

1.2 Use M10*22mm bolts, with corresponding anti-theft washers and nuts to fix the connecting plates A and B;

1.3 Adjust the verticality and horizontality of the metal mesh, and use special tools to fix the bolts and nuts firmly.

Installation requirements:

2.1 When installing the protective fence, it should be strict, neat, smooth and beautiful. No gaps should be left under the bridge, and the fence should be straight along the direction of the bridge.

2.2 When installing the fence, the ground on both sides of the fence should be leveled and compacted. When the fence is set on a slope or there is a height difference on both sides of the fence, the elevated part on both sides of the fence should be leveled to ensure that the fence reaches the protective height for the ground on both sides.

Mob.: 13663387126

Tel.: 0318-7967907

Fax: 0318-7967907

WeChat: 13663387126

Add.: 300 meters from Datong Xinnan, Anping County, Hengshui City, Hebei Province.