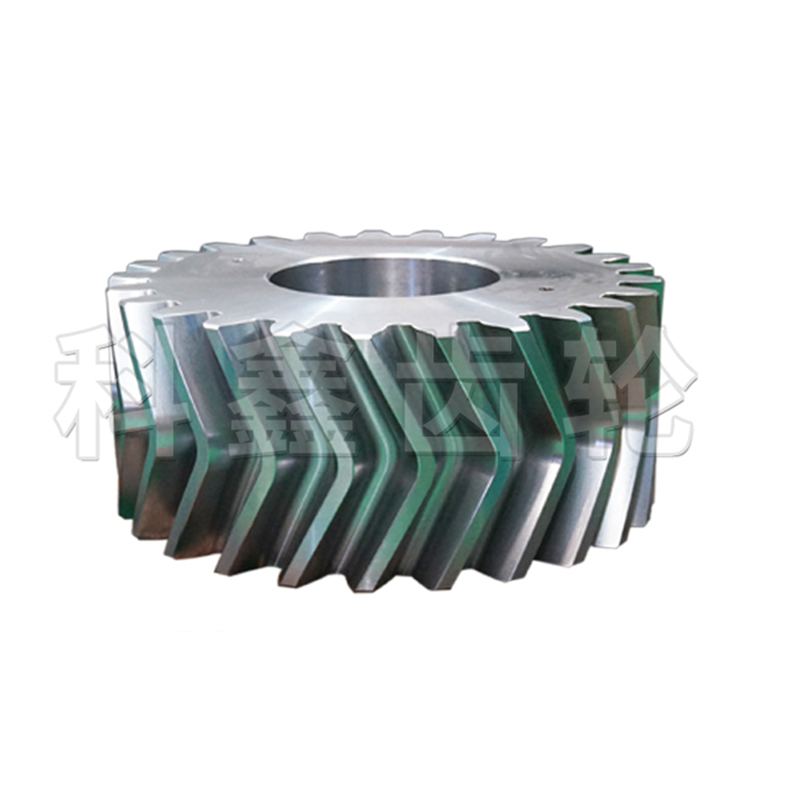

Herringbone teeth without undercut

Herringbone teeth without undercut

Product Description

Herringbone teeth without undercut refers to a specific type of gear design characterized by its herringbone-shaped teeth that do not have any undercut. This design feature enhances the stability and efficiency of the gear by eliminating the small recesses typically found in conventional herringbone gears. The absence of undercuts helps improve contact between mating gears, resulting in smoother operation and reduced noise levels. This design is particularly advantageous in applications requiring high precision, reliability, and minimal maintenance.

Advantages of Herringbone teeth without undercut

Design Advantage:

The herringbone-shaped teeth without undercuts enhance gear stability by providing continuous tooth contact.This design reduces the risk of misalignment and ensures smoother operation.

Manufacturing Technology:

Advanced manufacturing techniques are employed to produce these gears, ensuring high precision and exacting specifications. The lack of undercutting helps maintain the structural integrity of the gear teeth, leading to longer service life.

Operational Efficiency:

The design minimizes noise and vibration, resulting in quieter and more efficient gear performance.Improved contact between mating gears enhances load distribution and reduces wear.

Customization Options:

Gears can be custom-designed to meet specific operational requirements, including size, material, and performance criteria.Tailored solutions ensure seamless integration into diverse industrial applications, such as machinery, automotive, and engineering systems.

Quality Assurance:

Rigorous quality control processes are in place to guarantee the durability and reliability of the gears.The design contributes to minimal maintenance needs, reducing downtime and operational costs.

Application Suitability:

Particularly suitable for high-precision and high-reliability applications.

Ideal for industries where consistent performance and low maintenance are critical, such as heavy machinery, aerospace, and robotics.