Vacuum Brazing Furnace

High-temperature Vacuum Brazing Furnace can reach 1350℃, suitable for stainless steel, CBN tools, and Diamond tools brazing in the vacuum environment. Due to its high vacuum and high temperature, it can also be used for sintering and heat treatment of other workpieces.

Product Description

Vacuum Brazing Furnace is a process that produces high-quality joints in a vacuum atmosphere at temperatures of approximately 750°C to 1350°C. This also allows the joining of different materials such as ceramics and steel. This also allows the joining of different materials, such as ceramics and steel.

High-Temperature Vacuum Brazing Furnace, Molybdenum Chamber up to 1350℃

High-temperature Vacuum Brazing Furnace can reach 1350℃, suitable for stainless steel, CBN tools, and Diamond tools brazing in the vacuum environment. Due to its high vacuum and high temperature, it can also be used for sintering and heat treatment of other workpieces.

- Stainless steel brazing

- CBN tools brazing

- PCD tools brazing

- Diamond tools brazing

- Copper / sliver / nickel / aluminium base brazing

Advantages of Our Brazing Furnace:

- No surface oxidation or discoloration

- Minimal distortion

- Repeatable good brazing quality

- Clean, safe, quiet, and efficient

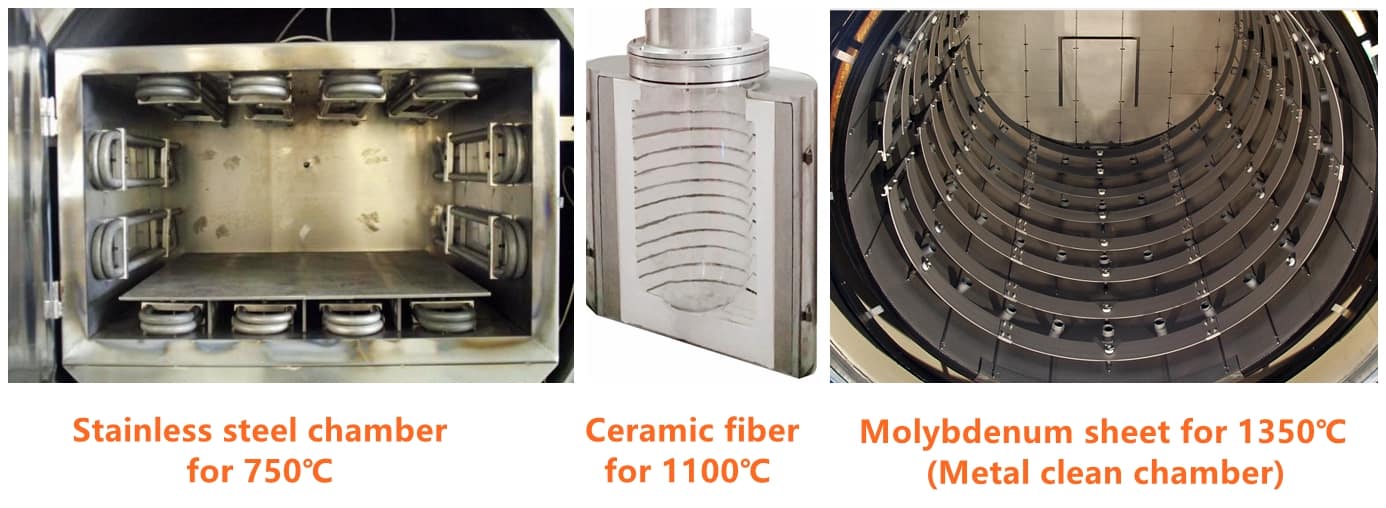

3 types of Furnace Chamber for optional

Detail of High-temperature Vacuum Brazing Furnace

Technical Specifications of Vacuum Brazing Furnace

Technical Specifications |

|

| Working Temp. | 750℃ (Alloy tube heaters) |

| 1100℃ (Heating wires) | |

| 1350℃ (Molybdenum strap heaters ) | |

| Furnace chamber | 750℃ (Stainless steel sheets) |

| 1100℃ (Ceramic fiberboard) | |

| 1350℃ (Molybdenum sheets and Stainless steel sheets ) | |

| Furnace Structure | Double layers Carbon steel casing with water cooling system to ensure the surface below 30℃ |

| The furnace door inside is polished stainless steel | |

| Working Voltage | 380V 50HZ 3P (or according to your standard) |

| Max. Power | 3KW–180KW |

| Temperature control system | |

| Temperature Control | 50 segments programmable and PID auto control or PLC |

| Upper limited alarm and deviation alarm | |

| Temperature Accuracy | +/- 1℃ |

| Heating Rate | < 20℃/min |

| Temperature Alarm | Over-temperature alarm |

| Broken thermal-couple alarm | |

| Thermocouple | K / S type |

| Touch Screen | 10 inches LED touch screen |

| Over 30 working programs can be set | |

| Heating curves can be saved | |

| Vacuum system | |

| Maximum Vacuum | 7×10-4Pa |

| Working Vacuum | 7×10-3Pa with Mechanical pump and Diffusion pump |

Standard Size: (other sizes can be customized)

Stainless steel chamber up to 750℃

| Model | Chamber size | Max Temp. | Power | Voltage | Max. vacuum |

| BR-QHS-223 | 200*200*300mm | 750℃ | 3kW | 380V | 7×10-3 Pa

(7×10-5 mbar) |

| BR-QHS-334 | 300*300*400mm | 750℃ | 6kW | 380V | |

| BR-QHS-446 | 400*400*600mm | 750℃ | 12kW | 380V | |

| BR-QHS-557 | 500*500*700mm | 750℃ | 18kW | 380V | |

| BR-QHS-669 | 600*600*900mm | 750℃ | 28kW | 380V |

Ceramic fiber chamber up to 1200℃

| Model | Chamber size | Max Temp. | Power | Voltage | Max. vacuum |

| BR-200BF | 1200℃ | 200x400mm | 8 | 380V | 7×10-3 Pa

(7×10-5 mbar) |

Molybdenum chamber up to 1350℃

| Model | Chamber size | Max Temp. | Power | Voltage | Max. vacuum |

| BR-QHS-223 | 200*200*300mm | 1350℃ | 42kW | 380V | 7×10-3 Pa

(7×10-5 mbar) |

| BR-QHS-334 | 300*300*400mm | 1350℃ | 72kW | 380V | |

| BR-QHS-446 | 400*400*600mm | 1350℃ | 120kW | 380V | |

| BR-QHS-557 | 500*500*700mm | 1350℃ | 160kW | 380V | |

| BR-QHS-669 | 600*600*900mm | 1350℃ | 225kW | 380V |

A typical vacuum brazing process is as follows:

Cleaning of the parts to be brazed

Brazing (foil, wire, solder paste, powder, plating) and assembly of the product

Setting up of the parts on the furnace rack

Furnace process (controlled by microprocessor)

Unpacking and cosmetic inspection

Testing / final inspection

The following aspects play an important role:

Cleaning of the parts to be brazed

Availability of the clean assembly room

Use of high vacuum ovens

Process variables

Loading tools

Testing facilities

The most important properties of vacuum-brazed joints are as follows:

Very strong and reproducible joints. Equal to or even stronger than the base material.

Corrosion-resistant joints are formed by using valuable brazing materials.

Joints may be exposed to relatively high temperatures (< 750 ºC)

Cleaning process. The product remains metal blank.

Flux-free brazing. Therefore, no undesirable surface reactions.

Very clean and hygienic gapless joints. Important for the food or medical industry.

Vacuum-sealed/leak-proof joints.

Various materials can be joined to each other (e.g., metal-ceramics).

Can be brazed and hardened in one process.

Parts can be hardened in almost all processes after brazing treatment.

High degree of construction freedom; can be thick/thin and can join large surfaces.

Multiple joints can be created in one process. Complex products can be created

A high degree of dimensional stability is possible, with no or almost no deformation

Labsnova(Zhengzhou Well-known Instrument & Equipment Co., Ltd) is one of a largest modern enterprises which include Research and Development(R&D), prototype design, product testing, advanced industrial production and excellent operation.

We have dedicated staff to give you a quote, please contact us if you need it!

Email: info@rotovap-wellknown.com

Mob.: +86 132 9817 7608

Tel.: +86 371 5507 3686

Whatsapp: +86 132 9817 7608

Add.: Changchun Road, High-tech Zone, Zhengzhou, Henan, China