Ethyl Acetate Production Plant

There are 4 main prevailing processes for ethyl acetate production, i.e. Direct Esterification Process, Acetaldehyde Condensation Process, Ethanol Dehydration Process and Acetic Acid-Ethylene Addition Process.

Product Description

Ethyl acetate is colorless transparent liquid, low toxicity, sweet smell, irritating odor at higher concentration, volatile, sensitive to air, can absorb moisture, making it slowly hydrolyzed and acidic reaction. Can be miscible with chloroform, ethanol, acetone and ether, soluble in water (10%ml/ml). Can dissolve some metal salts (such as lithium chloride, cobalt chloride, zinc chloride, iron chloride, etc.) reaction. Relative density 0.902. Melting point -83℃. Boiling point 77℃. Refractive index 1.3719. Flash point 7.2℃(open cup). Flammable. Vapor can form explosive mixture with air. LD50 (rat, oral) 11.3ml/kg.

Processed in these plants using top quality ingredients, our offered products are highly miscible with diethyl ether, acetone, ethanol & benzene and are widely used in nail polish remover & glues.

There are 4 main prevailing processes for ethyl acetate production, i.e. Direct Esterification Process, Acetaldehyde Condensation Process, Ethanol Dehydration Process and Acetic Acid-Ethylene Addition Process. Each process has its advantages and its applicable services. Our process is based on reactive-distillation esterification, which is mature, low costing and suitable for those with acetic acid feedstock. click here

Advantages of Ethyl Acetate Plant and Production

In our reactive distillation process, organic acid catalyst is used; its advantages cover the followings:

• Low ethanol consumption

• Low catalyst dosage

• High catalysis activity

• Low equipment corrosion

• Less side reactions

• Higher product purity

• Simple post-treatment operations

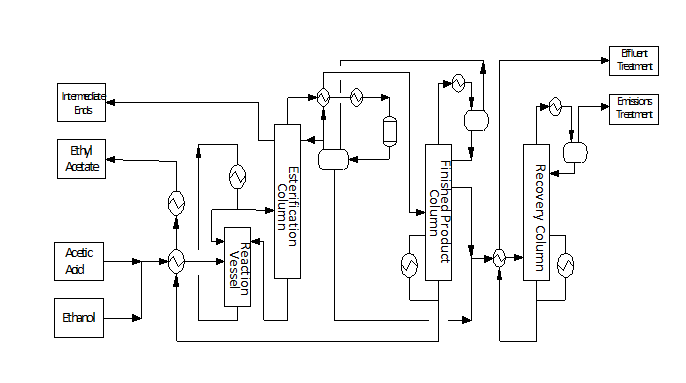

Simplified Process Flow Diagram

This diagram gives you a rough idea of how our ethyl acetate plant is configured.