Aluminum Strontium Alloy

Aluminum Strontium Alloy

Product Description

It is suitable for aluminum alloy metal mold casting (shock absorbing cylinder, cylinder head, etc.), sand casting, low pressure casting (wheel hub, etc.), die casting (engine cylinder head, etc.), and the preparation of grade alloy ingots and other industries. Refining and optimizing the structure of aluminum-silicon alloy (Si≤12%), the effective time of modification is 4-8 hours.

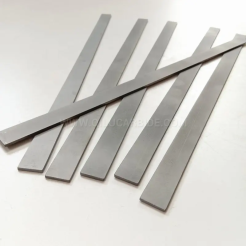

Aluminum-strontium Alloy Modifier-AlSr5、AlSr10

|

Product name |

Model No. |

Element content |

Shape |

|

Aluminum wire alloy |

AlSr5 |

5% |

coiled roll cut rod/cast bar/waffle ingot |

|

AlSr10 |

10% |

coiled roll cut rod/cast bar/waffle ingot |

Performance Characteristics

1. Aluminum strontium alloy is an aluminum-strontium master alloy containing 4.5-5.5% strontium and 9.0-11.0% strontium. It has an excellent microstructure and is a new type of excellent long-term modifier. This product optimizes the morphology and distribution of eutectic silicon and improves mechanical properties.

2. Aluminum strontium alloy is easy to use, non-polluting, minimal loss, long-lasting effect, and the effect of remelting and deterioration can be inherited.

Kingsun is a professional Master Alloy supplier. Whether you need more information, samples, a quote, or advice for a project, we would be delighted to talk to you.