Adhesive Tape

Product Description

https://www.htwrappingfilm.com/products/pe-film.html

Description

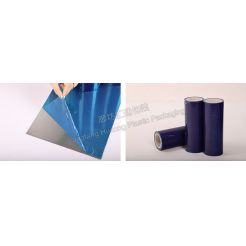

PE film, or polyethylene film, is a type of plastic film made from polyethylene. Polyethylene film is odorless, odorless, non-toxic and translucent. It is the most widely used polymer material in the world today. It does not react with moisture, grease, compounds, etc., is insoluble in most solvents at room temperature, and can withstand low temperatures of -70 ° C. Good weldability, good transmittance to oxygen and carbon dig aside, and poor permeability to water vapor.

Type

PE film is based on special polyethylene (PE) plastic film and is divided into high-density polyethylene protective film, medium-density polyethylene film and low-density polyethylene film according to different densities.

1. Low-density polyethylene (LDPE), the density of about 0. 92g/cm2; low-density polyethylene film has good transparency and heat sealing, can be waterproof and moisture-proof; but the tensile strength is low, the tensile elongation is large, and it is easy to wrinkle;

2. Medium-density polyethylene (MDPE), the density is about 0. 93~0. 94g/cm2; the performance is between high-density and low-density polyethylene;

3. High-density polyethylene (HDPE), the density is 0. 94—0. 965g/cm2; the heat resistance and mechanical strength of high-density PE film are better than those of low-density PE films, the tensile elongation is small, and the thickness of the film is generally above 0.03mm, but the transparency is poor.

In general, as the density rises, the mechanical properties and barrier properties will increase accordingly, heat resistance, and raw. Polyethylene of the same density also has different properties between them due to different film-forming processes.

Features

PE film is lightweight and flexible, making it easy to handle and transport.

It is resistant to moisture, making it suitable for use in damp or humid environments.

PE film can be sealed or heat welded to create a watertight barrier, making it useful for packaging applications.

It is also resistant to UV radiation and can be used outdoors without degrading.

PE film is generally very strong and can withstand high levels of stress, making it suitable for use in a variety of applications.

It has excellent mechanical strength, dielectric and moisture resistance, and can maintain softness and chemical stability at low temperatures.

Applications

PE film is often used in our lives, such as computer shell surfaces, screen surfaces, LED display surfaces, instruments, glass plate surfaces, etc.

PE film is commonly used in packagings, such as for food, beverages, and consumer goods. It can be used to wrap or cover products to protect them from moisture, dust, and other contaminants.

It is also used in construction, agriculture, and other industries. PE film can be used as a vapor barrier, a ground cover, or a protective layer for items such as machinery or tools.

PE film is often used in the medical field as a sterile wrap for instruments and equipment.

It can also be used for temporary coverings, such as for construction sites or outdoor events. PE film is strong and durable, making it suitable for use in a variety of different settings.