Jaw Solid Hydraulic Chuck

Adopt the advanced alloy steel material, all with the surface by surface hardening treatment, in order to improve the accuracy and durability.

Product Description

Jaw Solid Hydraulic Chuck

Elevate your machining precision and efficiency with the YS3 3-Jaw Solid Hydraulic Chuck. Benefit from superior clamping force, increased accuracy, and versatile workpiece compatibility. With its user-friendly operation and durable construction, this hydraulic chuck is a valuable asset for any machining workshop, delivering consistent and high-quality results.

Product Feature:

Adopt the advanced alloy steel material, all with the surface by surface hardening treatment, in order to improve the accuracy and durability.

With flange connection, A connection.

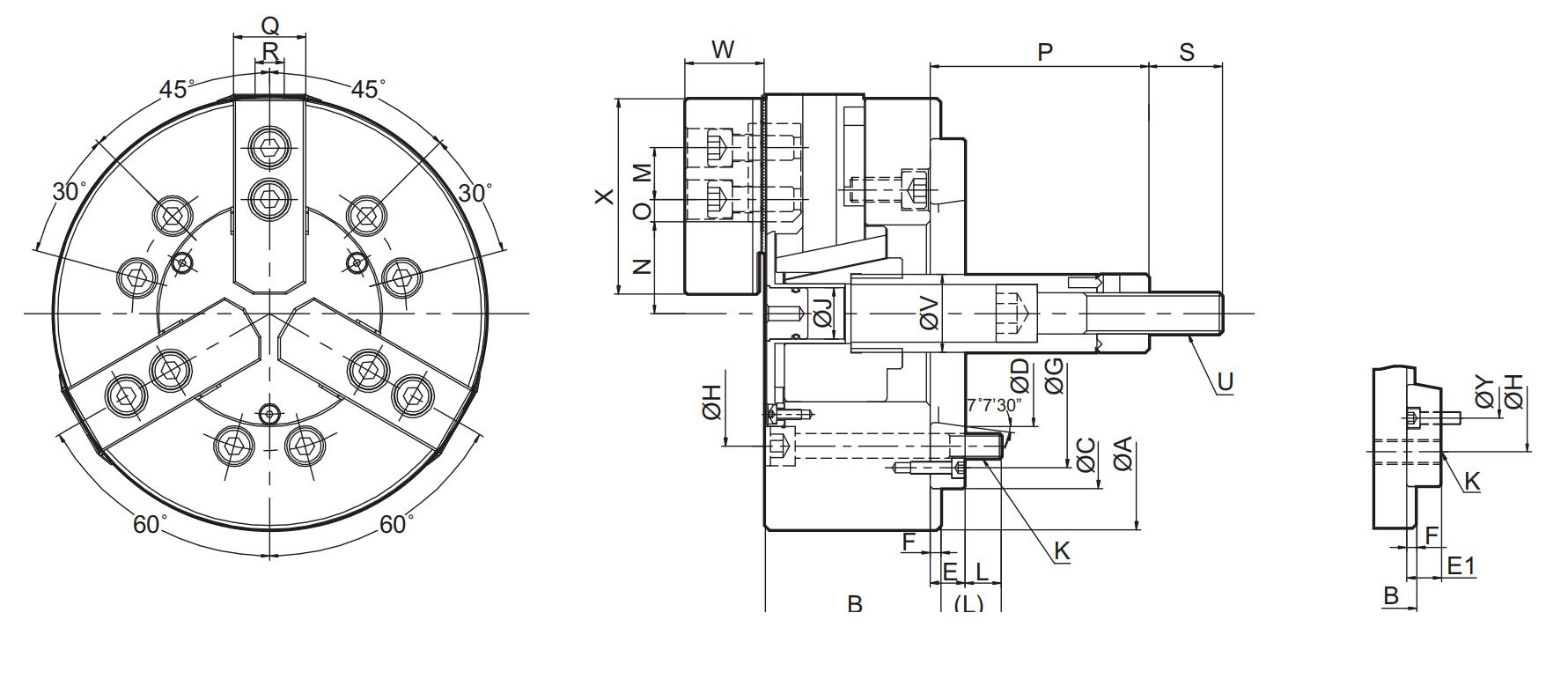

Product Size

Product Parameters

Performance parameters |

||||||||||

| MODEL/SPEC. | Nose Of Spindle |

Plunger Stroke (mm) |

Jaw Stroke (Diameter)(mm) |

Max.Speed (r.p.m) |

Max.Pull Force (kgf) |

Max.Gripping Force (kgf) |

Max.Hydr. Pressure (kgf/cm²) |

Net weight (kg) |

Matching Cylinder |

Gripping Range |

| YS3-05 | A4 | 15 | 5.4 | 5500 | 800 | 2450 | 22 | 6 | SH80 | Φ8~Φ135 |

| YS3-06 | A5 | 20 | 5.4 | 5000 | 1730 | 5200 | 27 | 11.4 | SH100 | Φ18~Φ165 |

| YS3-08 | A6(A5) | 21 | 7.4 | 4600 | 2440 | 7440 | 25 | 21.9 | SH125 | Φ26~Φ210 |

| YS3-10 | A8(A6) | 25 | 8.8 | 4000 | 2850 | 10810 | 29 | 33.4 | SH150 | Φ26~Φ254 |

| YS3-12 | A8(A6) | 30 | 10.5 | 3200 | 4080 | 15500 | 29 | 58.5 | SH200 | Φ26~Φ304 |

| YS3-15 | A11 | 35 | 16 | 2800 | 8260 | 25290 | 32.5 | 100.6 | SH200 | Φ50~Φ381 |

| YS3-18 | A11(A8) | 35 | 16 | 2500 | 8260 | 25290 | 32.5 | 134.3 | SH200 | Φ60~Φ450 |

| YS3-21 | A15(A11) | 35 | 16 | 1900 | 8360 | 27800 | 28 | 194 | SH200 | Φ60~Φ500 |

| YS3-24 | A15(A11) | 35 | 16 | 1750 | 8360 | 27800 | 28 | 246 | SH200 | Φ150~Φ630 |

| YS3-32 | A15 | 35 | 16 | 1750 | 8360 | 27800 | 28 | 350 | SH250 | Φ150~Φ800 |

| Size parameter | |||||||||||||||||||||||||||

| MODEL/SPEC. | A | B | C (h6) |

D | E | E1 | F | G | H | J | K | L | M | N max. |

N min. |

O max. |

O min. |

P max. |

P min. |

Q | R | S | U | V | W | X | Y |

| YS3-05 | 135 | 55 | 80 | 63.513 | - | - | 7 | - | 100 | - | 3-M8×1.25P | 14 | 14 | 30.4 | 27.2 | 17 | 7 | 9 | -6 | 25 | 10 | 35 | M12×1.75P | 28 | 31 | 62 | - |

| YS3-06 | 165 | 74 | 140 | 82.563 | 15 | - | 5 | 116 | 104.8 | 21 | 6-M10×1.5P | 14 | 20 | 37.8 | 33.25 | 18 | 7.5 | 101.5 | 81.5 | 31 | 12 | 36 | M16×2P | 34 | 39 | 73 | - |

| YS3-08 | 210 | 85 | 170 | 106.375 | 17 | 26 | 5 | 150 | 133.4 | 25 | 6-M12×1.75P | 18 | 25 | 46.3 | 41.9 | 22.5 | 9 | 127 | 106 | 35 | 14 | 36 | M20×2.5P | 38 | 42 | 95 | 104.8 |

| YS3-10 | 254 | 89 | 220 | 139.719 | 18 | 28 | 5 | 190 | 171.4 | 34 | 6-M16×2P | 25 | 30 | 51.4 | 47 | 37.5 | 10.5 | 158 | 133 | 40 | 16 | 36 | M20×2.5P | 45 | 46 | 110 | 133.4 |

| YS3-12 | 304 | 106 | 220 | 139.719 | 18 | - | 6 | 190 | 171.4 | 34 | 6-M16×2P | 25 | 30 | 60.7 | 55.45 | 47 | 11 | 163 | 133 | 50 | 18 | 36 | M20×2.5P | 50 | 54 | 130 | - |

| YS3-15 | 381 | 114 | 300 | 196.869 | 22 | - | 6 | 260 | 235 | - | 6-M20×2.5P | 32 | 43 | 77.5 | 69.5 | 50.25 | 23.25 | 104 | 69 | 62 | 25.5 | 55 | M30×3.5P | 60 | 63 | 165 | - |

| YS3-18 | 450 | 114 | 300 | 196.869 | 22 | - | 6 | 260 | 235 | - | 6-M20×2.5P | 32 | 43 | 108 | 110 | 49.5 | 25.5 | 92 | 57 | 62 | 25.5 | 55 | M30×3.5P | 60 | 63 | 165 | - |

| YS3-21 | 530 | 131 | - | 285.78 | 32 | - | 6 | - | 330 | 60 | 6-M24 | 31 | 60 | 86 | 78 | 93.5 | 27.5 | 97 | 62 | 65 | 25 | 55 | M30×3.5P | 60 | 70 | 180 | - |

| YS3-24 | 610 | 131 | - | 285.78 | 32 | - | 6 | - | 330 | 60 | 6-M24 | 31 | 60 | 125 | 117 | 93.5 | 27.5 | 97 | 62 | 65 | 25 | 55 | M30×3.5P | 60 | 70 | 180 | - |

| YS3-32 | 800 | 135 | - | 285.78 | 32 | - | 6 | - | 330 | 70 | 6-M24 | 31 | 60 | 99.4 | 89.4 | 212.5 | 32.5 | 35 | -3 | 65 | 25 | 73 | M36×4.0P | 102 | 82 | 185 | - |